Pre-load Control-typed Linear Guide

Low cost / Ultra-light / Ultra-slip / High Precision

New Revolution of LINEAR ACTUATOR

- 4-point contact mono carrier method

- The Linear Guide Rail and the Slide Block are integrated, so the repeat position accuracy, straightness and parallelism are excellent and there is no restriction in using the maximum speed.

- 100% company production guarantees quality assurance.

- Competitive price

- A/S technical support can be provided within 3 hours nationwide.

The flatness of the AL Profile Base (using 6N01 material) is thoroughly managed within 0.01 up to the maximum stroke. - No use of LM Rail enabled to reduce the Actuator’s width as well as its weight by more than 30% with the same specifications.

- With 100% company production, special orders can be promptly processed and customers??demands can be 100% responded.

- Regardless of the market situation, price, quality, delivery, A/S, technical support and customer services are provided stably.

Example of 3-axis combination

- The lightweight and compact structure allows various axis combinations.

- The lightweight can minimize the load during Y-axis and max stroke work.

KRT Ball Screw Type

KRT 043S | 050S | 060S | 080S | 100S | 120S | 130S | 150S | 180S

Characteristics

- Grinding & rolling Ball Screw Type

- Compact structure by Linear Guide Rail and Slider Block modularized

- Optimum to space-saving design

- High precision and high reliability securement by four-point contact structure

- Fulfillment lightweighting in comparison with existing products

- Use suitability at various industrial site required precision

- Not using the existing LM RAIL but using the special LM RAIL developed separately by us

- Patented products in Korea, US, China, Japan and EU

Inner Structure Diagram

KRT Belt Type

KRT 043T | 050T | 060T | 080T | 100T | 120T | 130T | 150T | 180T

Characteristics

- BELT TYPE

- Flexible installation through various combinations

- High precision and high reliability securement by four-point contact structure

- Compact structure by Linear Guide Rail and Slider Block modularized

- Optimum to space-saving design

- Fulfillment lightweighting in comparison with existing products

- Not using the existing LM RAIL but using the special LM RAIL developed separately by us

- Patented products in Korea, US, China, Japan and EU

Inner Structure Diagram

KRT Actuator Structure and Features

PROFILE LINEAR GUIDE

Product Structure

- All-in-one Linear Motion Guide

- L.M Guide Rail press-fitting structure in AL Alloy Profile

- 4-point ball Gothic Arch double-lining layout

- Integration of Guide and Stage allows the management of parallelism and straightness.

- Reduction of lubrication, wear and noise due to the resin ball grid layout

- Compatible structure of stage storage space

FEATURE

- Parallelism straightness 0.01/2000mm with the L.M Rail press-fitting grinding structure

- Compatible mounting of various operating devices through storage space (ball screw, linear motor, timing belt, air cylinder, rack and pinion and wire driver)

- High-speed driving (10m/sec with wire driver)

- Combination by management of reference surface when manufacturing Long Stroke

PROFILE LINEAR GUIDE

Load Test

- KRT130 Model Number Stroke: 1000mm

- Horizontal installation on the stone platform(load: 430kg)

- Friction load and allowable moment after loading

- Stage and Table deformation amount

End Result

- With the load of 430kg, friction load (1.2kg) – Push Pull Gauge

- Allowable Moment: Pitching M(747N.m) Yawing M(710N.m) Rolling M(1215N.m)

- Table and Stage elastic deformation amount (0.01mm) – Indicator

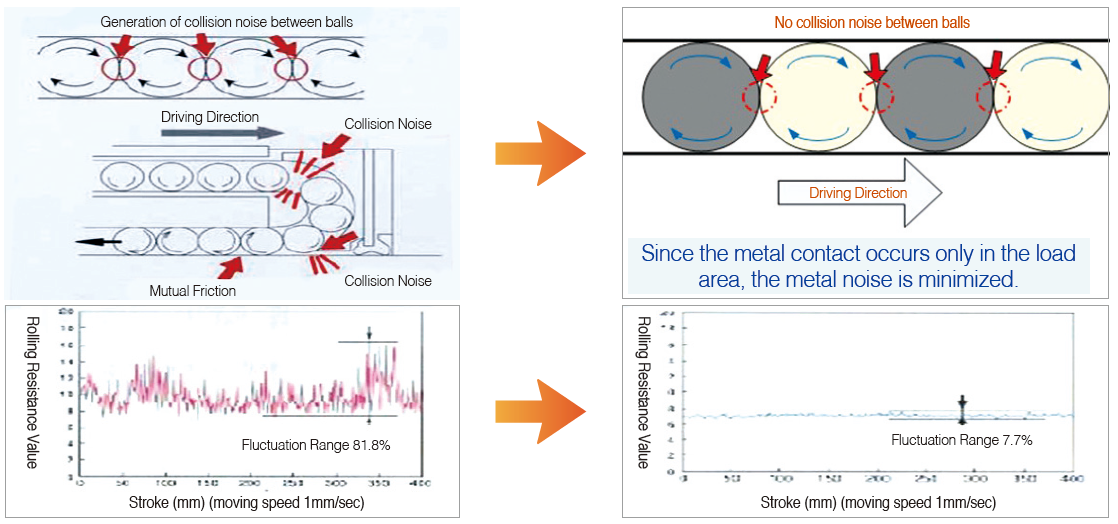

Resin Ball RETAINER

▶ Quiet driving by minimizing metal contact

- Quiet driving is possible due to no interference between steel balls and resin balls

- The adoption of resin balls removes friction between balls, which results in little wear of metal, low dust generation and less grease consumption. So, the injection period can be extended by more than 2 years.

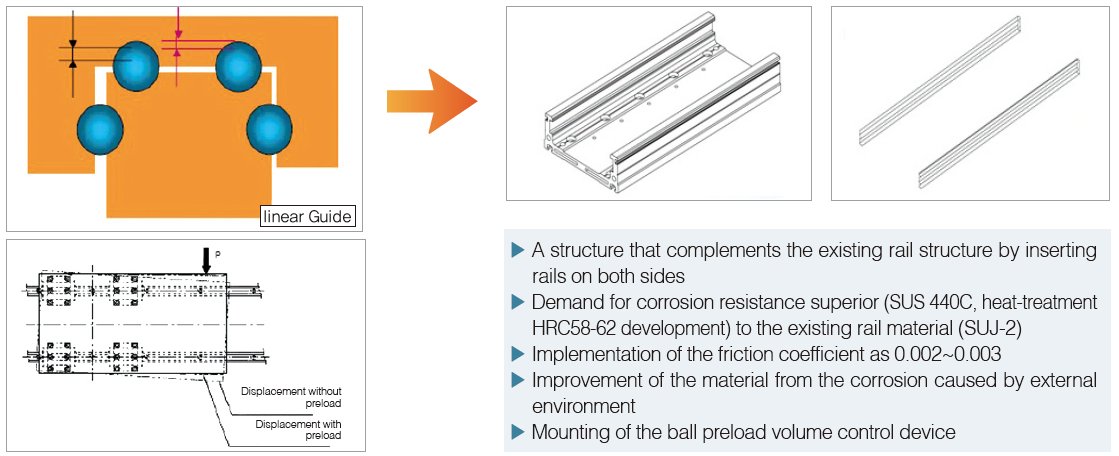

Mounting of Preload Control Device

▶ Preload and Effects of Preload

- Radial Clearance : When the profile is fixed and the block is lightly moved up and down from the center of the rail length direction, it is the amount of the movement in the radial direction from the center of the block.

- Preload : Internal load applied to the rolling ball in advance for the purpose of increasing the strength of the block and removing clearance